泉州聯進機械有(you)限公司

QUANZHOU LIANJIN MACHINE CO., LTD

切

條

機

用

說

明

用途:用于(yú)橡膠切條、切紙等(děng)

特點: 1.裝有防護裝(zhuang)置在使用時安全(quan)快捷。

2.翻滾切割,三(san)個刀片設計,切料(liào)速度快,效率高。

3.送(song)料速度可調,裁斷(duan)寬度可調。

主要技(ji)術參數 | |

LJ-CA08 | |

機型(xíng)Systems | 翻滾切 |

1200*1000*1200 | |

工作寬度Working Width(mm) | 600 |

功率Power (KW) | 2.25 |

重(zhòng)量Weight(kg) |

1. 操作時不要雙層(ceng)料同時切,以免燒(shao)壞電機,發現送料(liào)滾筒卷料時,要及(jí)時關機清理,同時(shi)如有雜料在刀口(kǒu)工作部位要及時(shi)清理幹淨,清理時(shi)務必斷開電源來(lái)源。

2. 原料不能(neng)有鐵,石頭等雜物(wù),如發現要清理幹(gan)淨,以免損傷刀片(piàn)。

5. 手搖加油泵一個(ge)星期加油一次,每(mei)次壓兩下;腳踏闆(pǎn)要輕踩輕放,以免(miǎn)兩頭軸心變位。

6. 如時間長,發現(xiàn)料切不斷①調整刀(dao)口間隙②修整刀口(kou),檢查刀口是否有(yǒu)損壞,如有損壞要(yao)及時修整。

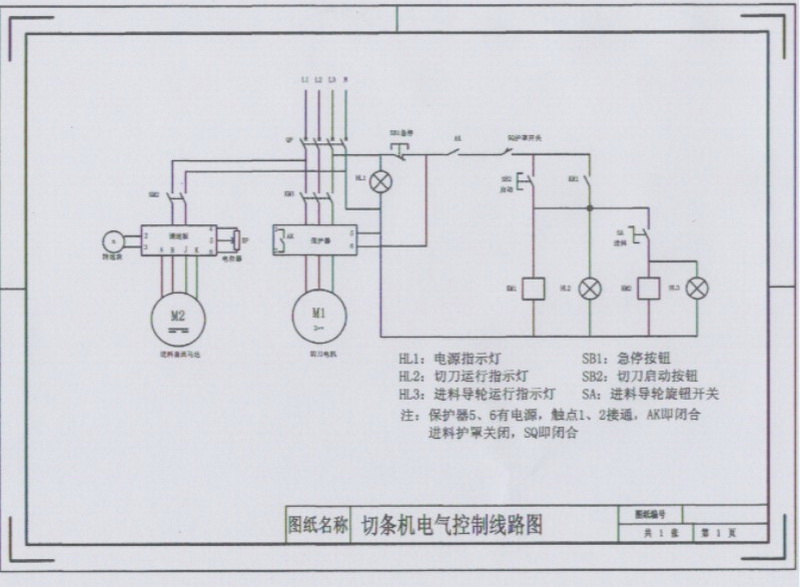

送(song)料滾筒如卡料,不(bú)能啓動①檢查電控(kong)箱内保險絲是否(fou)燒壞,如燒壞,更換(huan)時必需按原來型(xíng)号更換,不要随意(yì)加大規格。②檢查調(diao)整旋轉失靈,如有(yǒu)不靈及時更換。

8.兩端彈簧調整(zhěng)不能壓得太緊,以(yǐ)免滾卷料,新機台(tai)用少量粉撒在卷(juan)筒上,以免卷料。

Purpose: This machine is used for cutting the rubber, paper etc.

Advantage: 1.Equiped with safety cover to secure safety on working.

2. Revolving blade cuts rubber in high speed and efficiency, with three blade edges.

3. Adjusting with the width of rubber strip through the speed button on the side.

主(zhǔ)要技術參數 Technical Parameters | |

型号(hào) Model | LJ-CA08 |

機型Systems | 翻滾切 |

外型(xíng)尺寸Appearance Size: L*W*H(mm) | 1200*1000*1200 |

工作寬度Working Width(mm) | 600 |

功(gong)率Power (KW) | 2.25 |

重量Weight(kg) | 350 |

INSTRUCTIONS:

2. No iron or stone in the material; if any, take them, away at once, so as not to make the blade damaged.

3. Any unusual voice, stop and check. Adjust chains and screws if they are loose.

4. Do stop the machine when there is problem. Do not put hands in when the machine is still working.

6. After being operated for long time and the machine fails to cut off material, customer should adjust the knife and check whether the blade is damaged and need repairing.

7. In case the material sending roller can not send the material smoothly, you should firstly check and adjust rotary switch; if it can not work effectively, replace a new one in time.

8. Do not install the spring at each side too heavily or the material will not be sent smoothly. New machine please add proper amount of powder to the Rooller to avoid material rolling and jammed.

技(ji)術支持:廈門易爾(ěr)通網絡科技有限(xian)公司泉州分公司(sī) 信息支持:東南商(shāng)機網

京ICP證000000号