13559553569

泉州(zhou)聯進機械有(you)限公司

QUANZHOU LIANJIN MACHINE CO., LTD

動

沖

床

用

說

明

Hydraulic Automatic

Usage

用途:根(gen)據刀模裁斷(duàn)出需要的橡(xiang)膠片樣式

特(te)點:1.不漏壓!不(bú)漏油!零事故(gu)!

2.配置安全閥(fa),安全閥一打(da)開馬上停止(zhi)運作。

主要技(jì)術參數 Technical Parameters | |

機型Systems | 液壓式(shi)自動送料 |

外(wài)型尺寸Appearance | 850*1120*2030 |

刀模(mo)尺寸Knif mold size(mm) | 400*280 |

工作寬(kuān)度Working Width(mm) | |

總功率Power (KW) | |

重(zhòng)量Weight(kg) | 1000 |

主電(dian)源線:2.5平方毫(háo)米 三芯線

1. 油(yóu)箱的油保持(chí)幹淨,以免損(sun)壞油路的配(pei)件。

2. 加46# 液壓油(you)顯示油表至(zhì)80%。液壓油需每(měi)年更換一次(ci)。

3. 先馬達啓動(dòng),按上升下降(jiang)5-6次,再按自動(dong)。

4. 按照鞋模高(gao)度調整氣缸(gang)高低開關和(hé)油馬達的送(sòng)料時間長短(duan)。

5. 調定件數,按(àn)自動開關。

A.要(yao)檢查譯碼器(qì)的傳動齒輪(lun)是否有松動(dong),齒輪間隙是(shi)否過大。

B.檢查(chá)壓輥兩端彈(dan)簧是否過松(sōng)。

E.調整進料(liào)壓力閥和節(jiē)流閥。

F.如發現(xian)有阻料現象(xiàng),按照上面6中(zhōng)的D解決。并送(sòng)料一定要平(píng)整進入。

7.如發(fa)現料有切不(bú)斷

A.查看刀模(mo)是否平整。

8.油壓之最高(gāo)使用壓力爲(wèi)100kg/cm ,一般常用50-70kg.

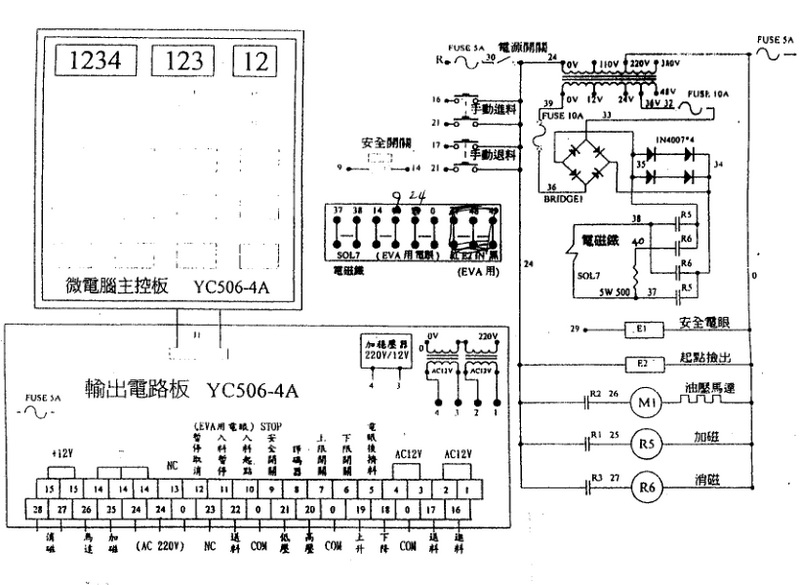

10.在正常使用(yong)過程中故障(zhàng)小,一般多爲(wèi)保險絲燒掉(diào),操作面闆損(sǔn)壞,電磁線圈(quān)損壞,電眼(傳(chuan)感器)沾粉。

Purpose:According to the knife mold cut out the required rubber sheet style.

Specialty: 1. No leakage in oil or pressure, safe.

2. It will stop working once the safety valve is open.

主(zhu)要技術參數(shu) Technical Parameters | |

型号 Model | LJ-D100 |

機型Systems | |

外型尺寸(cùn)Appearance Size: L*W*H(mm) | 850*1120*2030 |

刀模尺寸Knif mold size(mm) |

|

工(gong)作寬度Working Width(mm) | |

總功(gōng)率Power (KW) | |

重量Weight(kg) | 1000 |

INSTRUCTIONS:

Public equipment:Power: 380V,50Hz.

Host power line: 2.5mm² three -core

1. Keep the oil in tank clean, avoid damaging its accessories.

4. Adjust the cylinder HIGH-LOW button to set the cutting speed and time according to the height of shoe moulds.

6. If found the rubber cut being long or short unequally.

A. Check whether the transmitting gear of decoder work nomally, whether gear space is too big.

B. Check if the springs at two sides of roller are too loose.

C. Check whether the transmission chain too loose.

D. When feeding, the rubber must be through every gap bridge rollers.

C. adjust pressure valve.

8. The highest pressure in using is 100kg/cm about hydraulic oil, the nomal one being 50-70kg.

9. Piston & cylinder linner must be keep lubrication by adding oil once a week (when bubble appears)

10. Little fault under normal use, it is ordinary because fuse burned, panel damaged electromagnetic coil damaged, or powder attaches to transducer.